How many types of industrial and mining electric locomotives batteries?

Industrial and mining electric locomotives, also known as mining electric locomotives, are divided into wire-type industrial and mining electric locomotives, battery industrial and mining electric locomotives, lithium battery industrial and mining electric locomotives, and dual-power industrial and mining electric locomotives. Mainly transported by rail, underground or tunnel. The following will give you a brief introduction to the working principles and applicable environments of each of them to help you choose a product that is more suitable for you.

Wired industrial and mining electric locomotive

1. Working principle: After the high-voltage alternating current is stepped down and rectified by the rectifier cabinet, the negative pole is connected to the track and the positive pole is connected to the overhead wire. The pantograph on the locomotive is connected to the overhead wire, and the current is introduced into the vehicle, and then enters the DC traction motor through the automatic switch, controller, and resistance box to drive the motor to run. The electric motor drives the wheels to rotate through the gear transmission device, thereby driving the train to move. The current from the motor flows back to the converter via the rails. Speed regulation methods are divided into resistor speed regulation, chopper speed regulation and frequency conversion speed regulation.

Applicable environment: gas-free mines and tunnels.

Product features: low post-production costs and convenient maintenance.

Battery industrial and mining electric locomotive

1. Working principle: Battery-based industrial and mining electric locomotives are divided into explosion-proof and ordinary types. The working method is that the direct current provided by the battery enters the motor through the plug, controller, and resistor to drive the motor to run. The electric motor drives the wheels to rotate through the gear transmission device, thereby pulling the train to move. Speed regulation methods are divided into resistor speed regulation, chopper speed regulation and variable frequency speed regulation. Resistor speed regulation has been gradually eliminated in coal mines.

Applicable environment: It can be used in coal mines, metal mines or tunnel construction with gas. Compared with wired industrial and mining electric locomotives, it has a wider range of applications.

Product features: Batteries require frequent maintenance and replacement at intervals, resulting in high maintenance costs in the future.

Lithium battery industrial and mining electric locomotive:

1. Working principle: The battery industrial and mining electric locomotives are the same as above, but they are operated by the DC traction motor provided by the lithium battery. The motor drives the wheels to rotate through the gear transmission device and traction the train.

Applicable environment: Any mines and tunnels that do not contain gas. Currently, lithium battery industrial and mining electric locomotives do not have an explosion-proof certificate, so they cannot be used in coal mines.

Product features: Lithium battery power supply, maintenance-free, charge and use anytime, service life can reach 5-8 years.

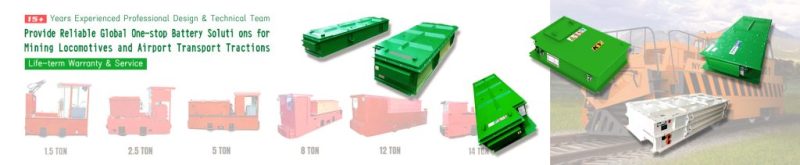

This kind of Lithium Iron phosphate battery for locomotives are what we can make for you. We have over 10 years experience in making and designing it. Using MA certified cells can guarantee the products safe and stable.

Dual power supply industrial and mining electric locomotives:

1. Working principle: The working reasons of the wired industrial and mining electric locomotive and the battery industrial and mining electric locomotive are combined. When running in the wired section, the traction motor mainly relies on the wired power supply for driving. At the same time, the battery power supply device The charging device can also obtain energy from the wired power supply to float charge the battery, supplementing part of the energy consumption of the battery when operating in the non-wired area, thus extending the use and maintenance cycle of the battery and reducing the maintenance workload of the battery.

Usage environment: It can be used in coal mines, metal mines or tunnel construction with gas.

Product features: High efficiency, can be used for continuous transportation at loading points in the alley.