Toyota bttery forklift Launches Latest Anti-Collision Sytem

Forklift safety has become an important technical upgrade for industrial vehicles, and the installation of safety auxiliary equipment has also been a means of forklift safety in recent years, from blue light to collision warning systems, and human-machine-related warning devices.

Last month, Toyota Forklift Japan released the latest forklift anti-collision system, which will be implemented in Japan as a standard configuration.

Toyota Industrial Material Handling Japan (TMHJ) introduces the “SEnS” forklift operator assistance system that detects and distinguishes pedestrians and objects behind the forklift, automatically controls the travel speed, and prevents the forklift from moving backward – assisting forklift operators by providing alerts and forklifts Control to identify pedestrians and objects behind the forklift.

Toyota Material Handling Japan (“TMHJ”), a division of Toyota Industries, Ltd. (President: Akihabara), has developed the “SENS+” forklift operator assistance system for pedestrian and object detection combined with the industry’s first forklift control function. The system distinguishes pedestrians and objects from obstacles behind the forklift and uses buzzers and lights to inform the operator of the method. In addition, it automatically controls the travel speed and prevents the forklift from moving backward based on conditions such as travel speed, the direction of movement, and distance to obstacles.

From August 26th, we started to provide this system for Ecore (8FBE series, three-wheeled electric forklift) and will gradually equip it on other models.

In recent years, automatic braking (collision damage mitigation braking) systems have been widely used in the automotive industry as one of the functions of safe driving assistance vehicles. As a result, functions supporting safe driving are evolving.

Forklifts are used in logistics sites where pedestrians and objects coexist, measures such as safety training programs and “separation of pedestrians and forklifts” are being promoted to prevent contact accidents between forklifts and pedestrians/objects.

The main features of SenS are as follows:

[SENS function overview]

A camera mounted on the rear of the forklift detects obstacles in the designated detection area, distinguishes pedestrians and objects using image recognition, and warns the operator in a timely manner with buzzers and lights. In addition, the travel speed and starting speed of the forklift are automatically controlled according to the forklift conditions such as travel speed and direction of movement (turning).

Unlike marker-enabled pedestrian detection systems, SEnS is able to detect unspecified obstacles (pedestrians and objects), so it can be used even when moving unspecified logistics stations.

The rear of the forklift has a horizontal angle of 130° and an industry-leading detection range of approximately 10 meters (32.8 feet).

The detection range is automatically adjusted based on a combination of multiple conditions, such as detection target, driving speed, and turning direction, to minimize unnecessary alerts.

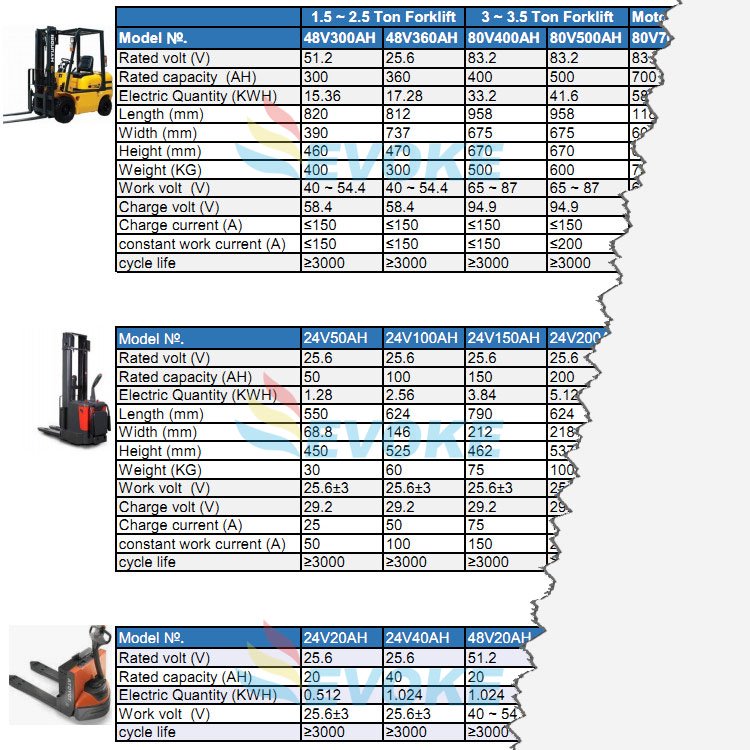

In the meantime, electric Toyota forklift battery market demand is growing rapidly while the material handling equipment business growing. Changing previous lead acid battery for Toyota forklift is no more the best solution, instead lithium-ion battery is more popular with Toyota forklift users or owners. Evoke energy team dedicated to material handling equipment battery design and replacement for over 9 years, with the best quality and good price, it has won a lot big market in the world. With our team’s asistant for you, your Toyota electric forklift battery maintenance will become much easier and less cost.

If you have such request, just emailed to us your enquiry to our email. Our team will design and caculate the best price for you soonest.

TIPS: Evoke Energy team, only dedicated to lithium iron phosphate battery and cells exporting.